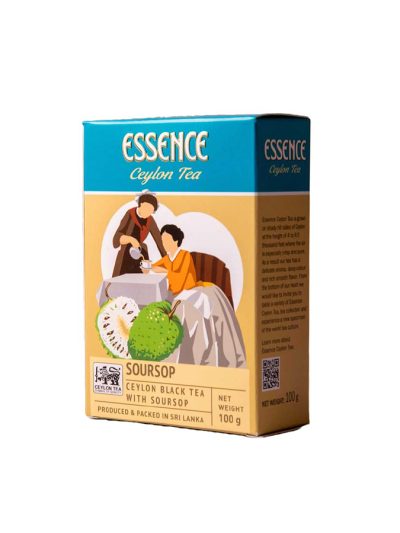

Indulge in the timeless allure of Pure Ceylon Black Tea, a symphony of flavors that transports you to the misty landscapes of Sri Lanka with every sip. Our tea encapsulates the very essence of its origin, where lush mountains cradle emerald tea gardens, and the art of tea-making has been perfected over generations.

Crafted with unwavering dedication by local artisans, our Pure Ceylon Black Tea is a tribute to a heritage that spans generations. With each sip, you’re invited to savor the spirit of Ceylon, its untamed beauty, and the mastery that transforms leaves into liquid poetry.

Embark on a journey that transcends taste, as Pure Ceylon Black Tea weaves stories of tradition, passion, and the vibrant soul of an island into your teacup.

Jeremypauri

11/11/2024Balanset-1A: Over 350 satisfied customers: Balanset-1A has proven itself on the market

electric motor balancing

Electric motor balancing is a critical aspect of maintaining the efficiency and longevity of electric motors. When a rotor within an electric motor is not balanced, it can lead to vibrations that cause excessive wear and tear on the bearings and other components. This is why properly balancing the rotor is essential for optimal performance. Let’s explore the basics of electric motor balancing, its significance, and the methods involved in ensuring that your electric motor operates smoothly.

At the core of electric motor balancing is the rotor. This is the rotating part of the motor that generates the electromagnetic field necessary for motor operation. For any rotor to function efficiently, its mass must be symmetrically distributed around the axis of rotation. If this symmetry is disturbed, an unbalanced centrifugal force arises, leading to vibrations. These vibrations not only affect the performance of the electric motor but can also result in serious damage over time.

To understand rotor imbalance, it’s essential to distinguish between two types of unbalance: static and dynamic. Static unbalance occurs when the rotor, at rest, has a heavy point that causes it to tilt or rotate unevenly under gravity. Dynamic unbalance, on the other hand, occurs when the rotor is in motion and is subject to centrifugal forces that create moments of imbalance. Each type requires different strategies for correction.

One common method for electric motor balancing involves adding compensating weights to the rotor. The goal is to locate these weights in such a way that they counteract the imbalance. This can be achieved through various techniques, which generally involve iterative testing and measurement to determine the correct size and placement of the balancing weights. This iterative method is commonly referred to as the three-start method or similar approaches that optimize the balancing process through systematic adjustments.

Different rotors may require specific balancing techniques depending on their design and application. Rigid and flexible rotors present different challenges. Rigid rotors maintain a consistent shape under operational forces, making them easier to balance using conventional methods. In contrast, flexible rotors may deform under stress, leading to complexities in balancing. This requires more sophisticated mathematical models to account for the deformation, which adds complexity but is crucial for effective balancing.

The significance of electric motor balancing cannot be overstated. An unbalanced rotor can cause vibrations that disrupt not only the motor itself but also associated machinery, leading to downtime and potentially costly repairs. In addition to vibration-related issues, an unbalanced rotor can lead to premature bearing failures due to excessive forces acting on the components. This can result in a significant loss of performance and increased operational costs.

To conduct electric motor balancing effectively, specialized instruments like vibration analyzers and portable balancers are frequently used. These tools allow for real-time measurements of vibration, which helps to pinpoint the problematic areas in the rotor. For instance, vibration sensors can continuously monitor the motor’s performance, providing data that can be analyzed to detect imbalances before they become severe.

However, it’s essential to acknowledge that balancing is not a standalone solution. While it can mitigate the risks associated with vibration and improve motor efficiency, it does not fix underlying mechanical issues. If an electric motor has misalignments or structural weaknesses, these must be addressed independently. Balancing provides a corrective measure but should not be viewed as a replacement for proper maintenance and repair procedures.

Moreover, understanding the natural frequencies of the rotor is crucial during the balancing process. Resonance can amplify vibrations significantly, making it challenging to maintain smooth operation. Careful analysis of the rotor’s natural frequency must be conducted to avoid operating in a resonant condition. This can often involve sophisticated analysis techniques or simulations to ensure that the operational frequencies do not align with the resonant frequencies of the system.

Lastly, various standards exist to guide the balancing process and assess its effectiveness. ISO standards, like ISO 1940-1-2007, specify permissible levels of unbalance for different rotor types. Compliance with these standards ensures that the motor operates within acceptable limits, thereby enhancing durability and reliability.

In summary, electric motor balancing is a vital practice that focuses on rectifying mass distribution within the rotor to prevent excessive vibration and wear. By understanding the different types of imbalance and employing appropriate methods for correction, you can ensure that your electric motor functions smoothly and efficiently. Regular assessment using advanced tools and adherence to established standards will not only extend the service life of the motor but also maintain its performance efficiency. Thus, investing time and resources into electric motor balancing is crucial for any operation relying on electric motors.

franshizi_zsMr

11/11/2024франшизы

сколько стоит франшиза сколько стоит франшиза .

prodvijenie saitov v moskve_tpOt

11/11/2024продвижение сайтов в москве

Интернет Партнер prodvizhenie-sajtov-v-moskve214.ru .

franshizi_mbMr

11/11/2024франшизы

список франшиз список франшиз .

prodvijenie saitov v moskve_otOt

11/11/2024продвижение сайтов в москве

seo продвижение сайтов москва seo продвижение сайтов москва .

prodvijenie saitov v moskve_lppn

11/11/2024продвижение сайтов в москве

москва продвижение сайтов москва продвижение сайтов .

franshizi_kbMr

11/11/2024франшизы

франшиза купить готовый бизнес франшиза купить готовый бизнес .

prodvijenie saitov v moskve_bkpn

11/11/2024продвижение сайтов в москве

сео продвижение сайта москва сео продвижение сайта москва .

servis nakrytki podpischikov_cwsa

11/11/2024сервис накрутки подписчиков

сервис накрутки подписчиков сервис накрутки подписчиков .

prodvijenie saitov v moskve_qfpn

11/11/2024продвижение сайтов в москве

продвижение сайта в топ москва продвижение сайта в топ москва .